Where Minting of Commemorative Coins was Revolutionized

Have you noticed that a large proportion of our commemorative coins today have a significantly higher relief than before? Behind this paradigm shift stands Reischauer, a private mint in Idar-Oberstein that combines state-of-the-art engineering with more than a century of experience.

In January 2016, at the World Money Fair’s Technical Forum, Dr. Gerd Wagner presented a development from the private mint Reischauer that would revolutionize the entire commemorative coin minting industry: Reischauer managed to produce special blanks not from repeatedly rolled strip material, but from metal powder. These blanks had completely different minting properties than traditional ones. They were easier to shape and could be precisely tailored to the final product during manufacturing. Coins made from these powder blanks are now ubiquitous in coin shops. In this article, we introduce you to Reischauer, the company where this development began.

Tradition, State-of-the-Art Engineering and a Wealth of Craftsmanship

The private mint Reischauer looks back on more than 100 years of history. Founded as a precious metal refinery to supply the emerging jewelry industry in Idar-Oberstein, Reischauer soon began producing semi-finished products for jewelers and fittings for fine leather bags. At the height of Idar-Oberstein’s prosperity, Reischauer employed more than 300 people . However, in the 1990s, globalization led to a shift in its traditional business focus.

This could have meant the end for Reischauer, had the company not already successfully developed a second pillar in the 1970s: the production of commemorative coins. This became their survival strategy when a large part of their premises fell victim to the devastating flood of 1995.

Since then, many commemorative and investment products have been created at Reischauer, especially after Dr. Gerd Wagner took over the company in 2001. The resourceful engineer committed his team to the motto with which Reischauer revolutionized the coin industry: “We can make it happen.” These words became a kind of mantra, a lived conviction for each of the approximately 65 employees. The experienced craftspeople, who average nearly 20 years of service at Reischauer, produce commemorative coins that no one would have thought possible before.

Since 2024, Reischauer has been part of the Pforzheim-based HM Group. Under the new Managing Director, Thomas Köninger, the staff looks forward to making the impossible possible for customers worldwide. “At Reischauer, we rely on good old German craftsmanship combined with state-of-the-art engineering. We are excited about all the challenges posed by the wonderful ideas our clients present to us worldwide,” says Thomas Köninger.

What is Actually the Secret of High Relief?

Let us first unravel the mystery of how modern mints, more than a century and a half after the obsolescence of the screw press, are once again producing reliefs such as were last seen on 19th-century medals.

Dr. Gerd Wagner adapted a technique previously used primarily in aerospace and for highly stressed engine components. Metal parts produced from powder, due to their crystalline structure, possess many properties desirable for coin production. They are far more deformable, which also applies to metals that are difficult to mint. Think of platinum in this context. The realization that this process could be used on a large scale for the coin industry will always remain the achievement of Dr. Gerd Wagner.

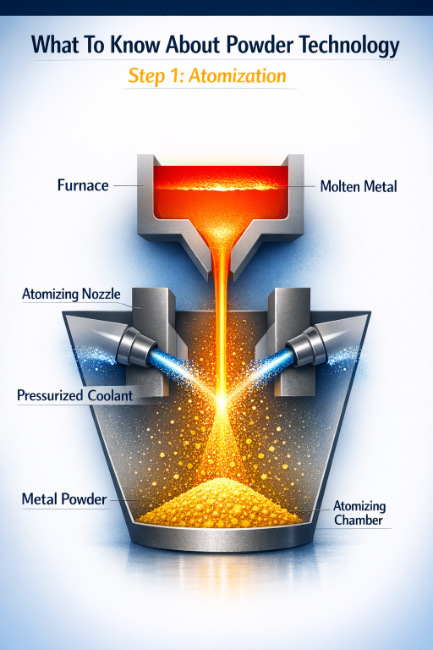

To produce a high-relief striking, powder of the desired alloy must first be created. For this, gold, silver, platinum, or any other precious metal with exactly the fineness the final product should have is melted down. The molten metal is not immediately poured into a mold, but rather atomized into tiny particles with the help of water. The resulting metal sludge is then dewatered in a multi-step process; the remaining powder is finely sieved.

Incidentally, one of the key advantages of this process is that it allows the creation of mixtures that are impossible to achieve through melting. Gold and osmium, for example, cannot be alloyed. However, by mixing their powders, it is possible to produce blanks made of a gold-osmium-mixture.

The powder now undergoes a process familiar to anyone who played in the sand as a child: the material is pressed into a mold. To make this mold durable, the material is sintered. Colloquially, this process is aptly described as “baking.” The powder particles bond together to form a flexible yet stable blank, often shaped so that the material is available at the points on the blank where it will later be needed for striking.

Before that happens, however, a thorough quality inspection is carried out. The Reischauer team ensures that every blank meets the high standards they set for themselves. Blanks that fail this test are immediately remelted.

Thomas Köninger says about this important business segment: “We now produce roughly as many blanks using the powder process as we do using the traditional process with strip and punching. We have perfected the powder process to such an extent that we can produce 2,500 blanks in a single 8-hour shift.”

Everything under One Roof

Reischauer prides itself on uniting all, absolutely all, processes of commemorative coin production under one roof, something many state mints no longer offer to this extent. This makes Reischauer extremely flexible, even when customer requests become a bit extravagant. Delivery times are also impressive. In urgent special cases, orders can be completed within 20 working days.

Let’s assume a commemorative coin is ordered. Even before preparing a quote, the sales team will consult with colleagues from production and design to determine the feasibility of the concept. What looks good as a drawing often doesn’t translate well to a die. At Reischauer, potential difficulties are discussed and designs are adapted before the problems even arise.

Once an order is placed, the first step takes place in the design department, where the customer’s designs are transformed into three-dimensional specifications for laser engraving. Even though embossing tools are now mostly manufactured using lasers, Reischauer employs engravers who have learned their craft from the ground up and can intervene in the die production process if necessary. This means that at Reischauer, the experienced human eye still decides what can be perfected and how.

While the striking tools are being manufactured, the corresponding blanks are already being produced in another department. Whether traditional blanks punched from strip material or powder blanks: Reischauer covers the entire process. For the classic blank, this includes alloying and melting, strip production, rolling to the desired thickness, punching, and edge finishing.

Because all processes are carried out in-house, Reischauer can offer not only standard blanks, but also deliver precisely the desired alloy as well as surprising shapes and sizes. The beauty of it: Employees have often worked through all departments and know exactly what their colleagues need. The entire team works hand in hand.

Finally come minting and finishing. Here, too, Reischauer masters all common techniques: from elaborate patination to color printing and electroplating, right through to packaging.

Good German Craftsmanship

While other companies focus on automation and speed, Reischauer prioritizes people and craftsmanship. This allows them to produce even small issues with spectacular designs, as desired by many collectors today. The team’s extensive experience ensures the efficient execution of even the most complex design ideas. At Reischauer, you’re not in a coin factory, but in a highly specialized workshop.

Plans for the Future

Reischauer has been around for over 100 years. Yet, visiting the operation today, one feels the sense of new beginnings among the team. Thomas Köninger, Managing Director of Reischauer, explains: “It’s a real advantage for us that, through our affiliation with HM – formerly Heimerle & Meule – we have several internationally established partners with whom we collaborate very effectively. This allows us to cover every conceivable customer need within the group. At Reischauer, we play the role of the highly specialized workshop within HM, capable of realizing even the most complex customer ideas. At the same time, we have our colleagues at our side, with whom we jointly cover virtually all the needs of the coin and investment market. This allows us to concentrate on what we do best: making the impossible possible. We love precisely translating great ideas into numismatic reality using most sophisticated technology.”

Eric Schröck, Head of Operations and Technology, adds: “I came to this company as an apprentice more than 35 years ago and have watched it grow. I’m delighted by the renewed energy that the collaboration with our partners at HM brings. Many of them are surprised about our Vertical Range of Manufacture.” Thomas Köninger adds: “My dream is that in a few years, every collector who holds one of our coins in their hands will know who we are and feel the passion with which we created their commemorative coin.”

Text and Images: Ursula Kampmann